Ensuring Integrity.

Enhancing Production

Our Solutions Trusted by Industry Leaders Worldwide

About Us

Vanguard Reservoir Surveillance

services (VRSS) is a leading company

in well integrity diagnostics, using cutting edge technologies to provide solution driven recommendations to enhance the life cycle of your wells.

Muscat

Proven Track

Record

Over 5,500 logging jobs completed since 2011, averaging around 500 logs per year.

Our Values

Our Strength

Cutting

EdgeTechnology

High Temperature

Capability

Customer-Focused Solutions

Vision-Driven Excellence

Proven Track

Record

Our Solutions

- Downhole Integrity Solutions

- DAS & DTS Fiber Optic Solutions

- EMDS Multibarrier Corrosion Logging Tool

- EPST Enhanced Passive Sonic Tool

- High Temperature Logging Tool

- MultiFinger Caliper Logging Tool

- Downhole Measuring tool PG-32T-C

- Downhole Measuring tool SDT-42T (Type 786T)

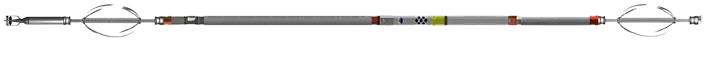

EMDS-4-P

Electromagnetic Defect-scope

Pulsed electromagnetic defect-scope is non-destructive corrosion logging tool which was designed to measure the individual wall thickness of concentric pipes in a single run that makes it the most cost-efficient corrosion evaluation tool in the market. The tool provides quantitative wall thickness measurement for up to 4 pipes and makes it possible to conduct thru-tubing corrosion survey in both single and double completions.

Applications:

- Quantitative 4 pipes corrosion evaluation

- Allocation of holes, cracks, “worn-out” areas, parted casing

- Allocation of casing/ tubing completion accessories, perforated intervals

- Applicable for single and dual completion design

- Time lapse corrosion monitoring

Real-time Enhance Passive Sonic Tool

Applications:

- Wellbore inflow/injecting profile

- Formation active intervals

- Crossflow between active formation intervals.

- Qualitative analysis of formation saturation across non-perforated intervals.

- Upwards and downwards crossflow.

- Quantitative 4 pipes corrosion evaluation

- Allocation of holes, cracks, “worn-out” areas, parted casing

- Allocation of casing/ tubing completion accessories, perforated intervals

- Applicable for single and dual completion design

- Time lapse corrosion monitoring

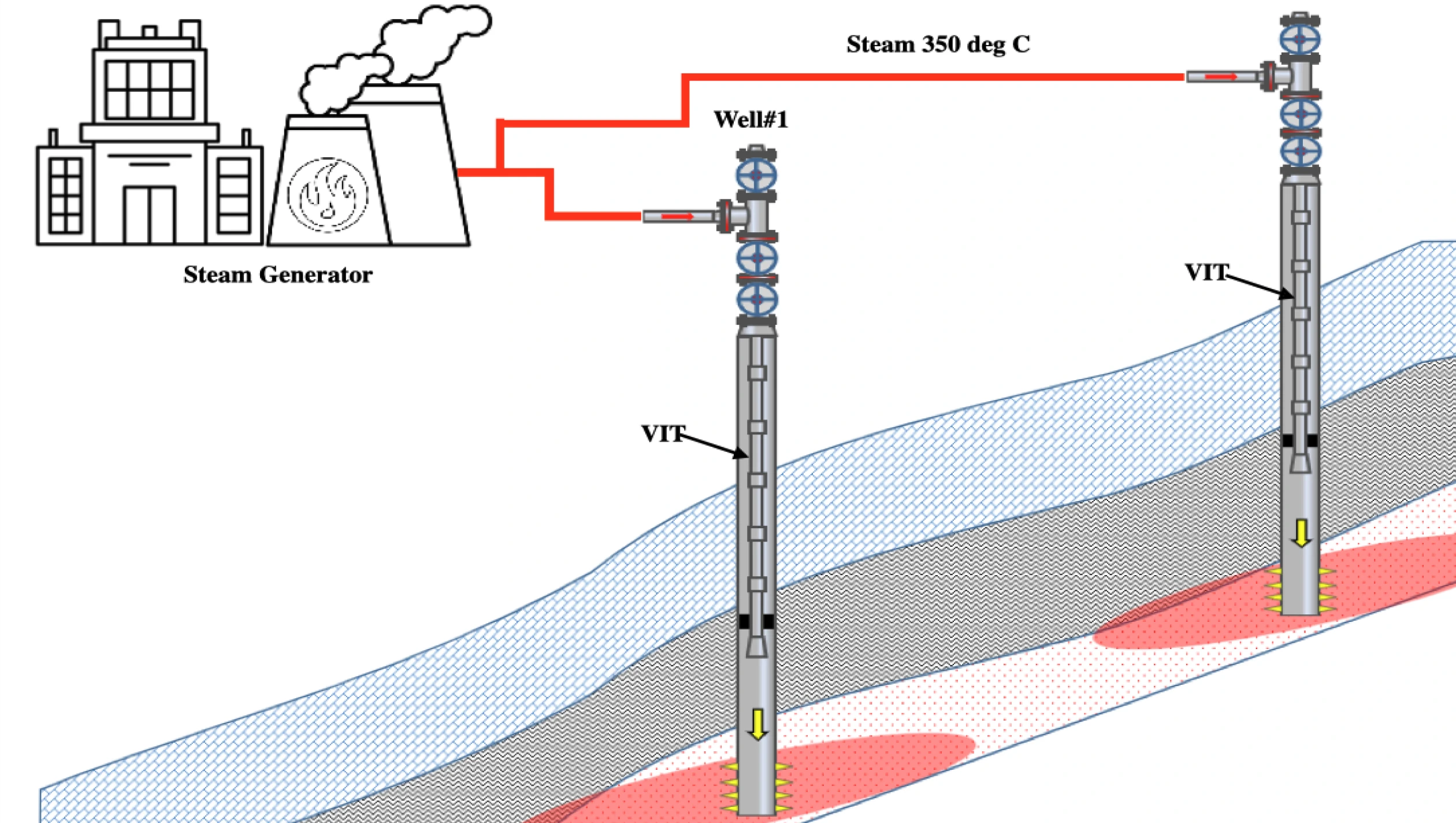

Real-time High Temperature Tool

The High Temp Downhole Tool is designed to conduct logging in hush wellbore environment. Tool includes following sensors: Temperature, Pressure, Casing Collar Locator, Gamma Ray and conventional flow meter (spinner, turbine type). Tool work in real time with mono-conductor cable. Acquisition system allows to monitor all recorded data in real time and take decision with no extra time to make decision.

Applications:

- Identification of steam injection profile across perforated intervals. Steam phases distribution along wellbore.

- Identification of production profile in geothermal wells.

- Leak point hunting.

- Cross flow identification.

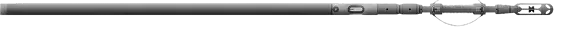

Real-time Multi Finger Caliper 40 Logging Tool

The High Temp Downhole Tool is designed to conduct logging in hush wellbore environment. Tool includes following sensors: Temperature, Pressure, Casing Collar Locator, Gamma Ray and conventional flowmeter (spinner, turbine type). Tool work in real time with mono-conductor cable. Acquisition system allows to monitor all recorded data in real time and take decision with no extra time to make decision.

Applications:

- Internal metal loss of pipe (general, holes, cracks, wears, “worn-out” areas).

- Pipe deformation

- Scale accumulation on inner wall of the pipe

- Identification of perforated intervals

Downhole Measuring tool PG-32T-C

Downhole Measuring tool PG-32T-C is a memory pressure gauge designed to deliver reliable and accurate downhole pressure data. With proven piezo-sapphire sensor technology and a robust design, the tool ensures stable long-term performance in demanding well…

Downhole Measuring tool SDT-42T (Type 786T)

Downhole Measuring tool SDT-42T is a standalone memory logging tool that operates on the principle of acoustic impact sensing. As sand particles travel through the wellbore and strike the surface of the tool’s high-frequency sensor, they generate mechanical impulses.

Applications:

- Zonal Sand Entry IdentificationIdentification of intervals contributing to sand production for targeted intervention planning and sand control strategies.

- Production OptimizationAnalysis of sand production data to determine the safest and most efficient production regimes, minimizing erosion risk while maintaining output.

- Flowback AnalysisMonitoring sand and proppant returns during post-fracturing flowback operations to assess formation behavior and completion efficiency.

- Erosion Risk AssessmentEvaluation of erosion risks to downhole and surface equipment based on measured sand intensity and particle load.

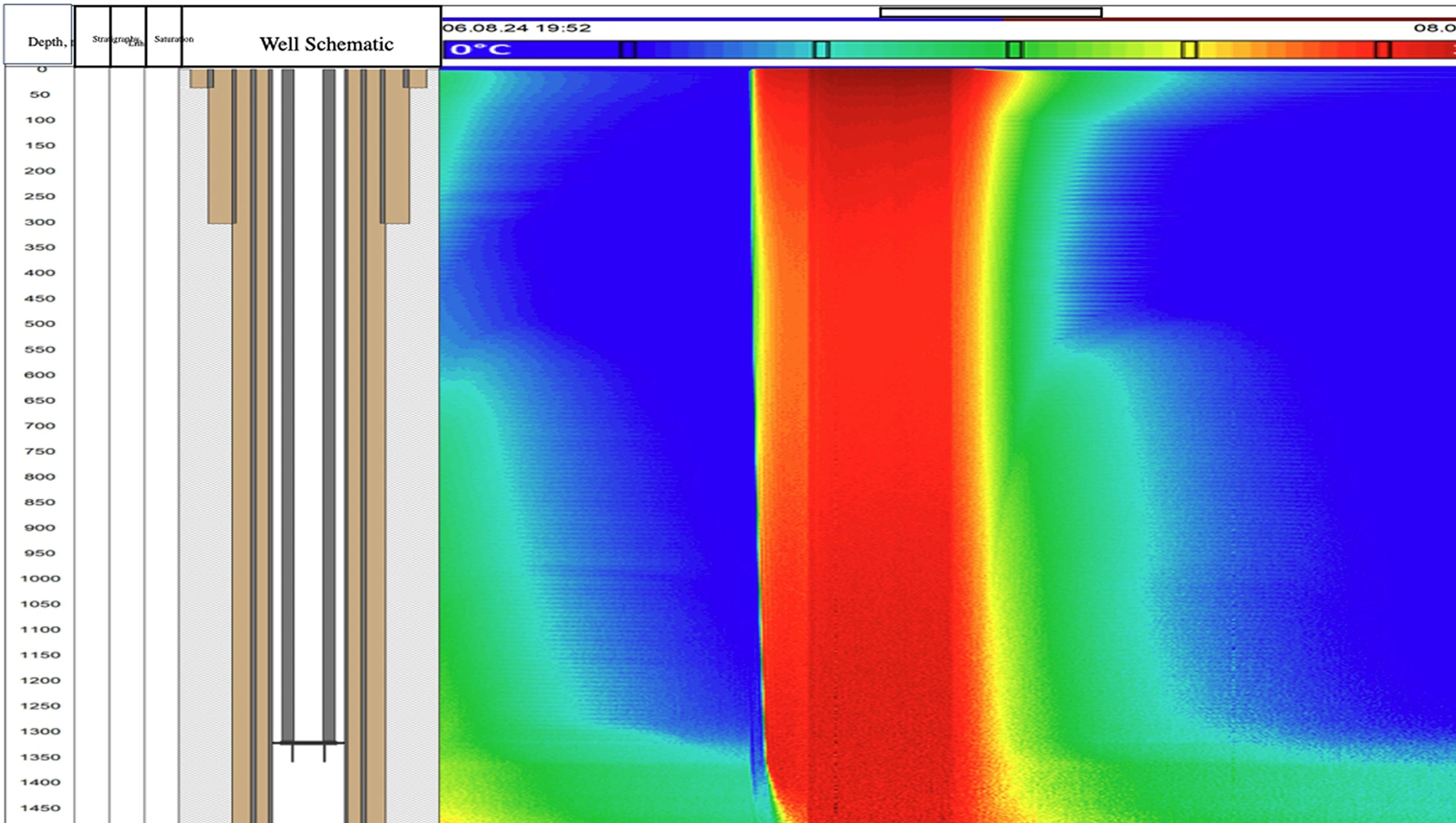

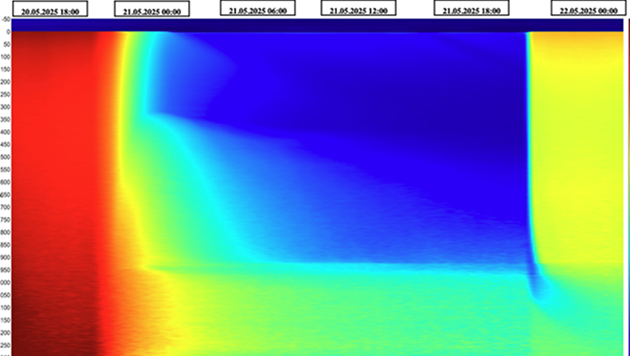

- DTS Application

- DAS Application

- Integrity Status of VIT collars

- Steam Leak below TD

- Temperature Profile Across Entire Logging Interval

Integrity Status of VIT collars

Applications:

- Integrity status of VIT collars

- Integrity status of completion string & casing accessories

- Temperature distribution profile across logged interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

Steam Leak below TD

Applications:

- Integrity status of VIT collars

- Integrity status of completion string & casing accessories

- Temperature distribution profile across logged interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

Temperature Profile Across Entire Logging Interval

Applications:

- Integrity status of VIT collars

- Integrity status of completion string & casing accessories

- Temperature distribution profile across logged interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

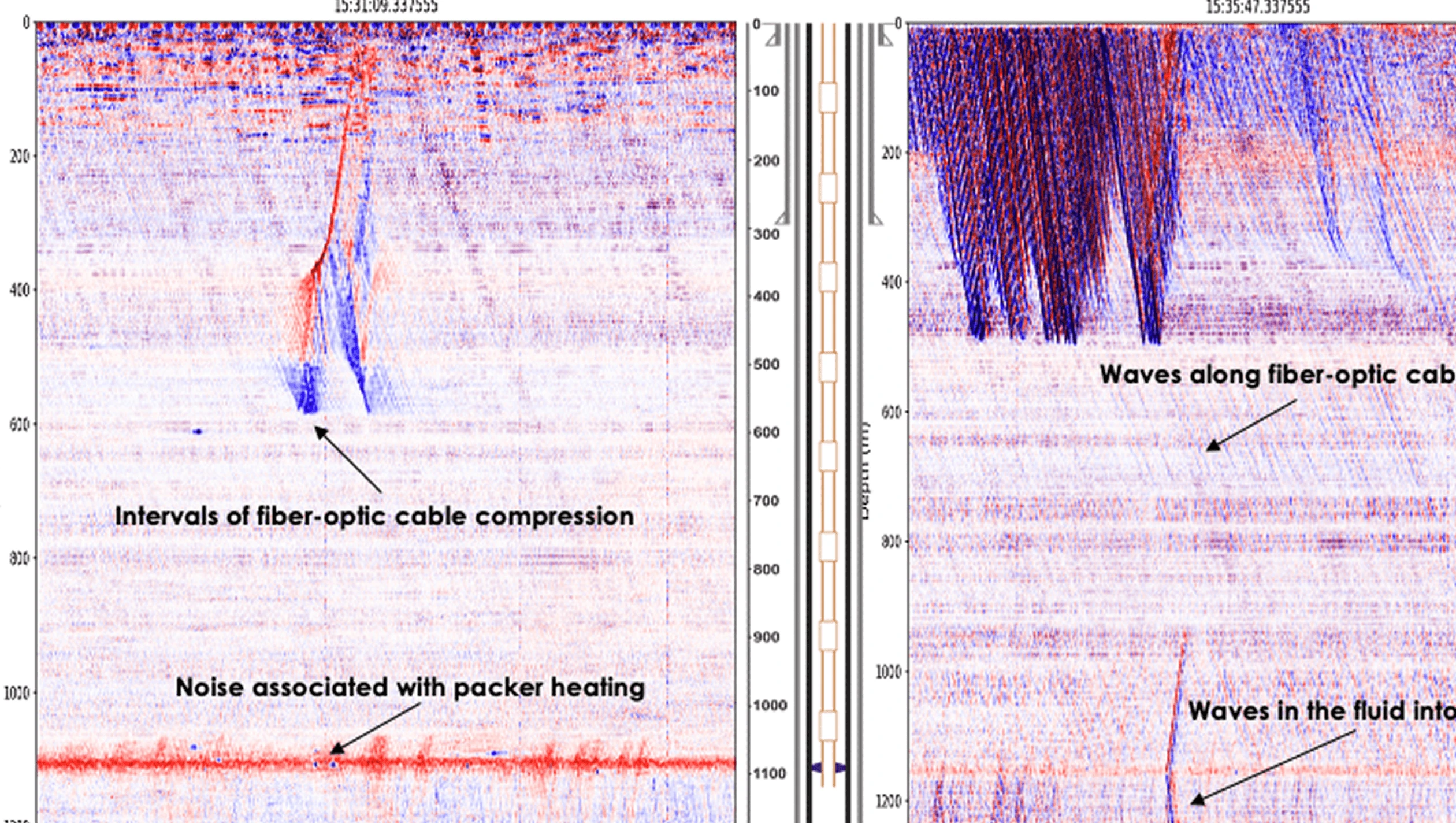

- Noise Method

- Interferometry Method

- Seismic Events Location

- Acoustic Waves Velocity Analysis

Noise Method

Applications:

- DAS status of VIT collars

- Integrity status of completion string & casing accessories

- Type of fluid across entire logging interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

- Different regimes of two-phase flow

- Quality of cement bonding

- Fluid level in the wellbore

Interferometry Method

Applications:

- DAS status of VIT collars

- Integrity status of completion string & casing accessories

- Type of fluid across entire logging interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

- Different regimes of two-phase flow

- Quality of cement bonding

- Fluid level in the wellbore

Seismic Events Location

Applications:

- DAS status of VIT collars

- Integrity status of completion string & casing accessories

- Type of fluid across entire logging interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

- Different regimes of two-phase flow

- Quality of cement bonding

- Fluid level in the wellbore

Acoustic Waves Velocity Analysis

Applications:

- DAS status of VIT collars

- Integrity status of completion string & casing accessories

- Type of fluid across entire logging interval

- Injection & Production zones across perforated interval

- Quantitative Calculation of injection & production profile

- Different regimes of two-phase flow

- Quality of cement bonding

- Fluid level in the wellbore

Our Products

Integrity Challenge

It is important to have a good cement bond in the annulus, for example by using a multistage packer and having adequate centralization. External coating on the inner pipe will lessen the risk of corrosion migration from the outer pipe to the inner pipe. This is especially key if the outer pipe has poor cement quality or no cement and is exposed to a corrosive aquifer. Multiple barrier failure can lead to catastrophic consequences such as an oil leak to surface which could result in damage to personnel, the environment, the asset and company reputation.

Accurate Dynamic

Reservoir Modelling

A PLT is a common logging tool which provides flow profile inside the wellbore only. This type of tool cannot provide the formation flow profiles as well as crossflow above-between-below perforated intervals. If only PLT log data is used for 3D dynamic modeling this could lead to discrepancies in the dynamic reservoir model which could affect further field development. The log data from the SNL acoustic tool can identify which intervals are accepting water in water injection wells and which intervals are producing in production wells. With the log data from the combination tool this will improve the accuracy of the dynamic reservoir model and ultimately improve recovery such as identifying un-swept oil saturated areas which could be targets for future infill drilling.

PLT and Temperature Logging

The well is a vertical barefoot steam injector which was drilled in 2009. After drilling the well was completed with a 13 3/8” conductor, 9 5/8” surface casing and 7” intermediate casing. A 4.5” pre-drilled liner (PDL) was installed across the barefoot section. The steam was injected through vacuum insulated tubing (VIT). A PLT was conducted in 2022 with the main objective to obtain the injected steam profile and distribution across the barefoot section. In addition, several relaxation temperature passes were recorded to understand the formation intake zones. The relaxation passes were recorded as follows: after 72 hours, 80 hours, 96 hours, 104 hours, 120 hours, 128 hours, 134 hours, and 144 hours of shut-in.

Integrity Challenge

From previous case studies it is evident that in artificially lifted wells with either a bean pump (BP) or a progressive cavity pump (PCP) wear areas and associated corrosion are visible. This is caused by the sucker rod (SR) couplings as they are reciprocating or rotating over the same intervals against the wall of the tubing, the additional friction of the coupling on the tubing can cause wear and ultimately compromise the tubing integrity. The additional friction i.e., drag can also result in an impairment to the pump performance and a reduction in production.

R & D Capabilities

Developing advanced and modular downhole technologies

With a goal to increase the depth and accuracy of investigation and tool behavior in myriad of pipe configurations, an advanced calibration facility was built in the Nimr operational base of VRSS situated south of Oman. Numerous series of tests have been conducted using different sizes and grades of API standard pipes to find the optimal magnetic field to cater depth of investigation, vertical resolution, number of measurable pipes, types of defects.

Calibration Facility – The Backbone of Our R&D

Purpose-built facility enabling precise tool calibration for EMDS multibarrier tools

Uses physical modeling for accurate metal loss calculation, improving interpretation quality

Facilitated the next level of tool accuracy and developments

Client-focused workshops held regularly to explain EMDS technology, metal loss evaluation, and field applications

We aspire to be the number 1 Integrity Solution Provider globally.

Milestone ofSuccessful Journey

VRSS Established

High Temperature Tool

First Generation of Multi Barrier

Corrosion Tool EMDs ( Two barriers )

First Long-Term Corrosion Service

Contract Signed

Second Generation of Multi Barrier Corrosion

Tool EMDs ( three Barriers )

VRSS Expanded Services in GCC

First Generation of Acoustic

Modular Tool

Calibration facility established

in NIMR for Multi Barrier Corrosion tool

VRSS Expanded Services in North Africa

Third Generation of Multi Barrier

Corrosion Tool EMDs (Four Barriers)

Introduction of Multi-Finger Caliper tool

(MFC) combination with EMDs

Enhance Passive Sonic

Tool

Pre-qualified VRSS technologies in

ADNOC

- Introduced new generation of EMDS

- Introduced new solutions – Sand Detection and Downhole Gauges

- Introduced Fiberoptic DAS and DTS solutions

Media

“VRSS is dedicated to providing top-tier services while upholding the highest HSE standards. We recognize the persistent challenge of corrosion and its potential catastrophic consequences and tackle it head-on by providing cutting-edge tools that will deliver accurate data and solutions.”

Executive director's messageLet's Start Building

Unforgettable Events Together

Have questions, or ready to explore how Stroud can transform your event? Fill out the form below, and our team will get back to you shortly. We’re here to make your vision reality.